Discover how you can boost your terminal operations and increase efficiency of product movements using our Tload terminal automation solution.

Running a bulk liquid or solids terminal is a very challenging task. The following are just some of challenges facing today’s terminal operators:

- Wrongly executed transactions (bills-of-Lading);

- Reversing and rebooking transactions;

- Faster communications with the billing (ERP) system;

- Reducing the complexity of loading process and move to unmanned loading;

- Automating the blending process and increasing the number of recipes;

- Reducing manual effort, waist and lost product;

- Increasing safety during loading and product movements;

- Controlling carrier access and insurance status;

- Checking allocations and credit at the time of loading;

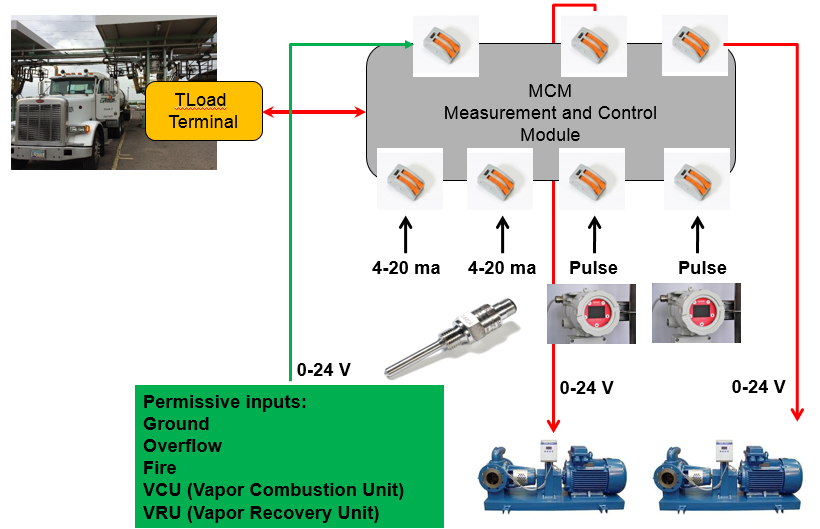

- Automate the permissive inputs prior to loading;

- Multiple shippers at the same physical terminal;

- Planned, unplanned and deal based loads.

Brochure

Tload is our latest state of the art in terminal and rack automation technology designed to handle all challenges facing today’s terminal operators. Tload is used in any terminal or load rack in order to automate and track the movement of any product using any mode of transportation (truck, rail, pipeline etc.) In additional Tload provides access control, carrier insurance tracking and tank gauging.

If you are a terminal owner or operator then Tload is the perfect solution for all your terminal and rack automation needs, no matter the size of you operation.

Tload is used to load and manage any product stored at a loading facility such as:

- Refined products

- Crude

- Chemicals and other bulk liquids

- Asphalt

- Mining ores, coal, sulfur and other bulk solids

- Agricultural bulk products

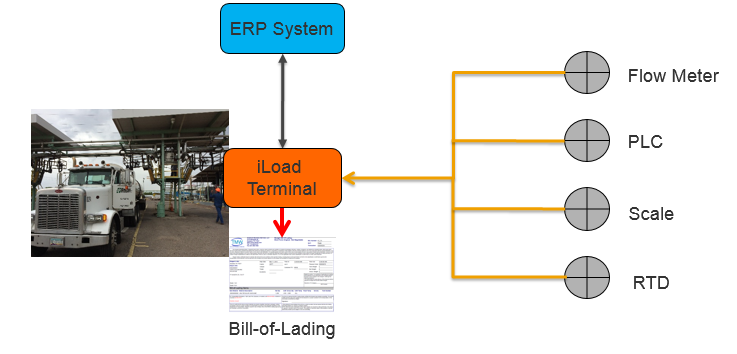

Tload utilizes the latest touch screen technology to provide a user friendly interface that can be used by drivers and terminal loaders. The interface is customizable to suit your business process at the individual terminal. The Tload hardware (terminal or station) is installed at load rack and wired into existing automation infrastructure.

Tload is configured to suit your needs for each terminal in terms of the number of:

- Load racks;

- Load arms;

- Recipes;

- Connection to meters, scales, RTDs, PLCs etc;

- Permissive inputs

Tload supports all loading and movement scenarios terminaling and throughput is also supported and governed by the shipper including:

- Sales;

- Purchases;

- Transfers.

All loading scenarios can be executed in a number of ways:

- Unplanned loading,

- Planned loading (Order Based Loading);

- Deal Based Loading.

In a planned transaction, the driver/loader enters a planned order number (which is previously created and approved) and the loading occurs with reference to the planned order. In an unplanned transaction, the driver picks the customer, product etc from a drop down on a menu touch screen station.

Tload terminal can also incorporate driver access cards which can provide transaction information to the load rack such as carrier info, deal number, driver info etc. The type of information supplied by the access cards can be configured to suit your business needs.

The MCM (Measurement Control Module) is critical part of the Tload, it is programmable microprocessor that is able to communicate to any hardware like meters, RTDs, PLCs, scales, etc….

MCM is used to control the loading process at load arm. The following illustrates gasoline blending.

The MCM is wired to existing control wiring at the load rack in order to perform the tasks of measuring and controlling the loading process. MCM will blend into your existing automation environment and can talk to any hardware.

Tload communicates to any ERP in a number of ways: FTP, webservice, real-time etc.

With regards to SAP Tload offers seamless integration using SAP certified components built inside SAP that enables total management of the terminal from within SAP. This approach has the following benefits:

- Eliminates the need to separate code for products, customers, carriers in the local automation system.

- Exposes the breadth of SAP system to Tload terminal (driver and loader) in order to perform functions like credit check.

Tload can be deployed in 2 ways:

- Hosted solution

- Local install

Key Features:

- Customizable driver/loader interface;

- Reverse, rebooks and returns;

- Credit checks;

- Allocation checks;

- Flexible reports;

- Communication with SAP is delivered with the SAP components.