Load Rack Optimizer (LRO)

Optimizing the volume or the number of trucks or railcars for a particular load rack/bay can be challenge for most businesses. If too many vehicle show up at same to load the shipper will incurs demurrage charges and if too little vehicles to show up to load it means the load rack/by is not fully utilized. The ideal situation is to have one vehicle show up for each time slot, for example if loading a truck takes 30 min then ideally a new truck should show up every 30 mins.

LRO (Load rack Optimizer) is a software tool that helps your business to achieve maximum use of your load rack/bays thus improving the plant efficiency reducing demurrage truck idle time.

Load Rack Optimizer, Plan, Do, Check and Act

With LRO you can plan ahead the load rack schedule by allocating planned orders or trucks to certain time slots in the future, you can easily view time slots with conflicts or too many orders. LRO also allows you allocate drivers, tanks, loaders to any planned order using drag and drop. From LRO you will be able to print work load reports by load rack or by loader.

LRO is customizable to suit the specific business needs of your company, including the number of load rack/bays and specific scheduling activities of your business.

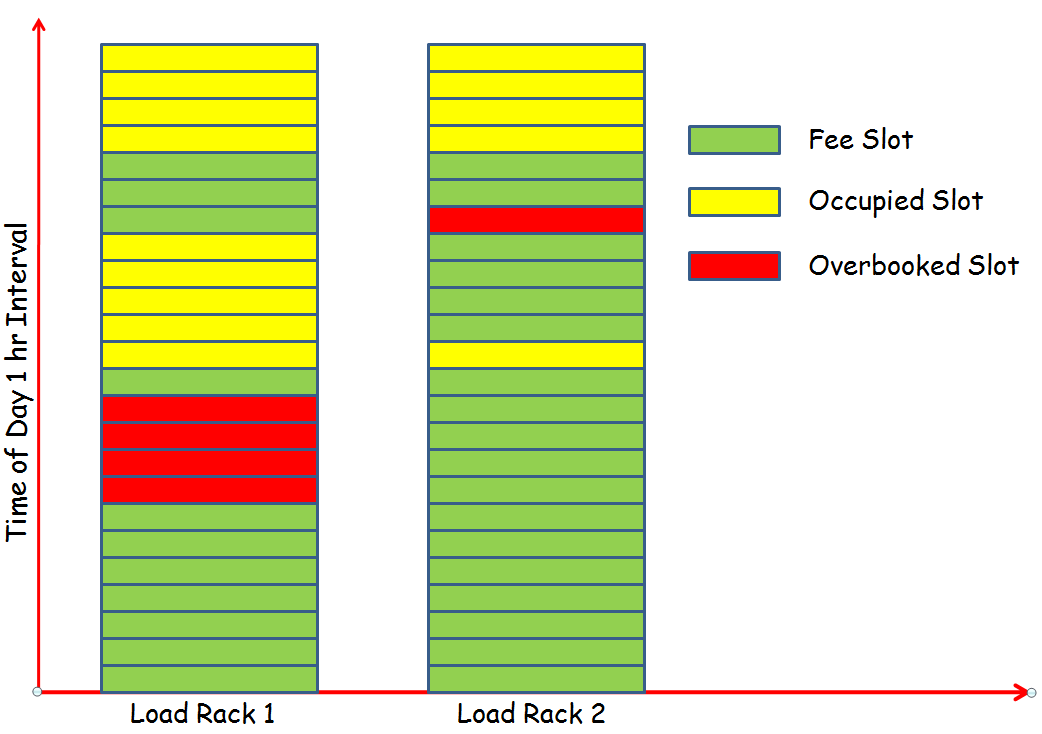

LRO Display of Time Slots and Allocation

LRO shows a daily view of loading racks/bays by time slot, time slot can be 15, 30, 45 or 60 mins. Each time slot will be highlighted in a different color based on whether the slot is free, booked or over- booked. Orders can be dragged into any time slot.

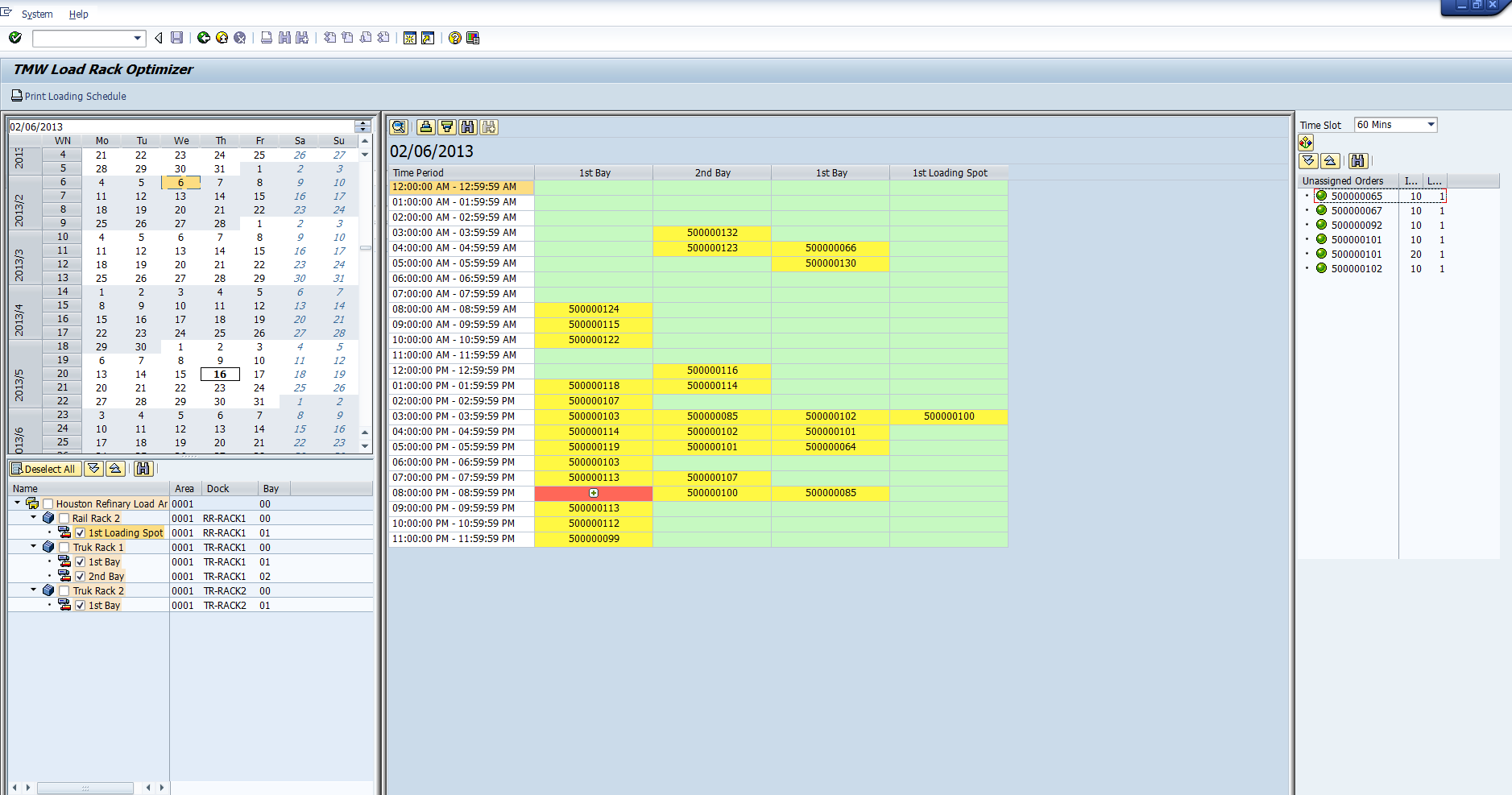

LRO SAP Scheduling Screen

Load Rack Optimizer is an add-on to TMW-planned order is built within the ABAP language certified by SAP. LRO integrates seamlessly with TMW and it serves the following business functions:

1- Allows order entry person to identify free time slots within a load rack as soon the order is entered.

2- Allows planners and schedules optimize the use of loading racks and available time slots.

LRO has graphical front-end with drag and drop capabilities in order to optimize the use of load racks. Planners are able to do the following:

- View all load racks (load bay) usage by 15 min, 30min 45 min, 1 hr, day, week and month

- View orders not assigned to a load rack (bay) and drag and drop an order on a particular time slot.

- View racks or time slots with conflicts.

- Print loading schedule by load rack, bay or load person.

- Assign assets to each order like truck, railcar, tank, loading person etc.

- Update planned orders from with LRO.

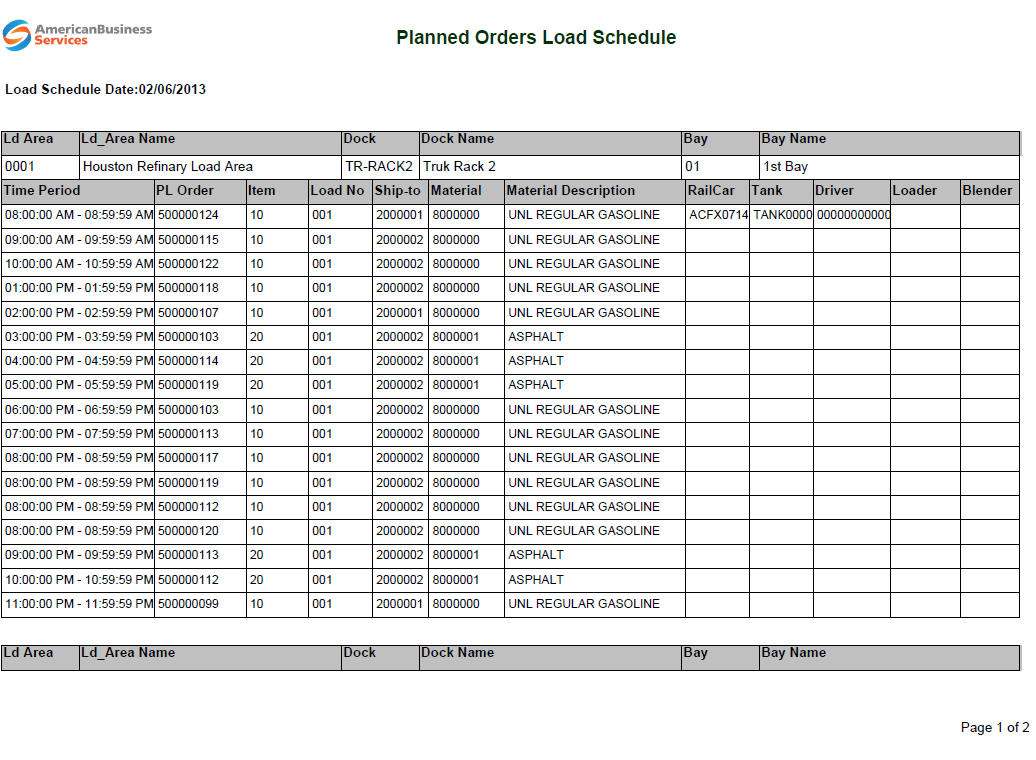

The following shows a sample report produced by LRO.

Business benefits for LRO: